Here you will learn about the topic of Ball Mill in Pharmaceutical Engineering, subject B Pharma Course. So let’s start with our tagline, Dream, Believe, Achieve.

Table of Contents:

Introduction:

Have you ever wondered how paint gets its vibrant colors, or how some medicines are so powerful? The answer might lie in a fascinating machine called a ball mill. This is a powerful grinding machine used to make materials extremely small. Picture a rotating drum containing hard balls, like steel marbles. As the drum spins, the balls crash into the material inside, breaking it down. By changing things like the ball size, rotation speed, and materials used, you can control just how tiny the final product becomes. Ball mills are essential tools in industries like medicine manufacturing, mining, and even pain production.

Principle:

Ball Mill is like a grinder that crushes materials into tiny particles by hitting them together and rubbing them against the walls of the container. The basic principle behind all this is impact and attrition.

Impact:

- As the this machine rotates, the balls inside are lifted along the walls of the cylinder.

- When they reach a certain height, gravity makes them fall back down to the bottom.

- This powerful falling action creates an impact force that crushes the material within the mill.

Attrition:

- The balls don’t just fall; they also slide and roll against each other and the material being ground.

- This constant rubbing and grinding further breaks down the material into smaller particles.

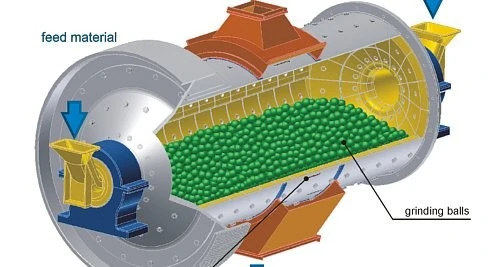

Construction of a Ball Mill:

Ball mill have various parts, so we learn them one by one.

Key components:

- Cylindrical Drum (shell): (A) This is the main body of the ball mill, a hollow cylinder that rotates. (B) The shell is usually made of a tough metal like steel and has an extra layer of protection inside (like rubber or manganese steel) to prevent it from wearing down too quickly.

- Grinding Media (Balls): (A) These are the hard objects inside the drum that do the grinding. (B) This is composed of steel, ceramic, or other hard materials. (C) The size and quantity of balls are chosen based on the material being ground.

- Drive Mechanism: A motor and gear system rotate the cylindrical shell at a controlled speed.

- Feed Inlet and Discharge Outlet: Openings to put material in and take the ground product out.

Construction Basics of a Ball Mill:

- The Shell: A large metal cylinder is fabricated, with a length slightly larger than the diameter. It’s lined with a protective material to prevent wear and tear as the balls tumble inside.

- Mounting: The shell is mounted onto a strong frame that supports its weight and allows it to rotate smoothly.

- Drive System: A motor and gears are connected to the shell so it can be rotated at a controlled speed.

- Inlet/Outlet: Openings are made at either end of the cylinder for loading and unloading material.

- Grinding Media: The correct size and number of balls are added to the shell.

Important Considerations:

- Speed: The speed of rotation is critical. Too slow, and grinding won’t be effective; too fast, and the balls will stick to the walls due to centrifugal force.

- Material Compatibility: The lining material needs to be chosen based on what’s being ground to avoid contamination.

- Safety: Ball mills can be noisy and potentially hazardous, so safety features and protocols are needed.

Types of Ball Mill:

- Dry: No need for water in this.

- Wet: Water or another liquid is required.

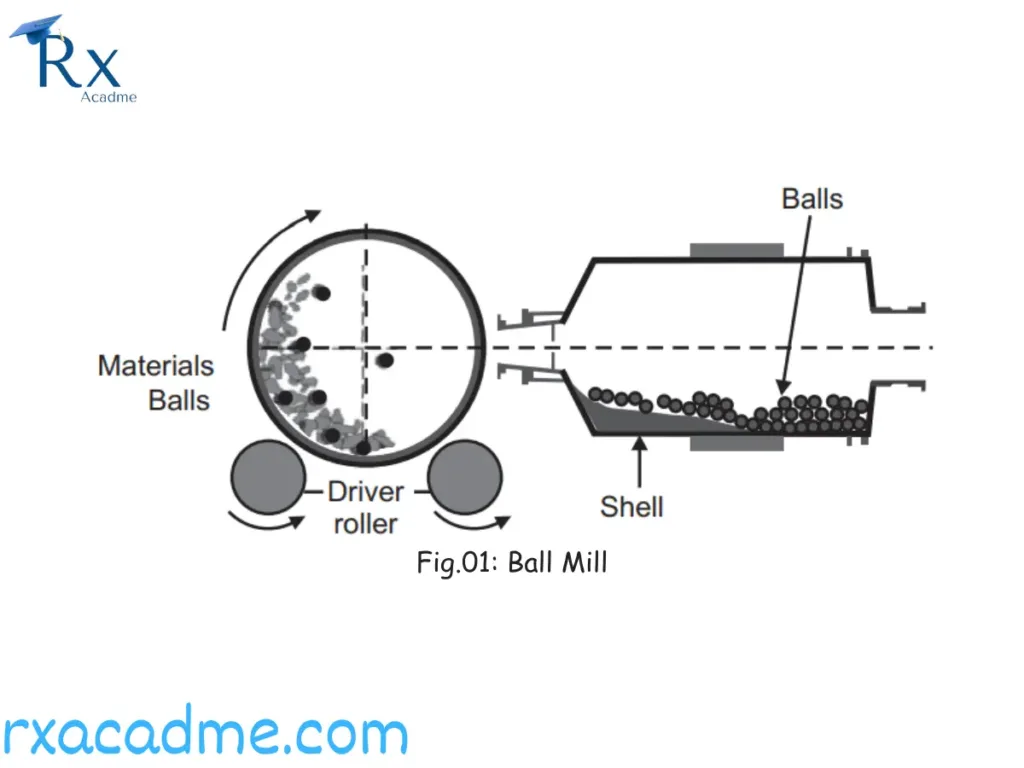

Ball Mill Diagram:

Working of a Ball Mill:

The grinding process:

- Loading: The material to be ground is fed into the ball mill’s cylindrical shell through the feed inlet. The mill is partially filled with grinding media (usually steel, ceramic, or flint balls).

- Rotation: The motor and gear system start rotating the shell. The speed of rotation is critical and varies depending on the material being processed.

- Impact and Attrition: Inside the rotating shell, the grinding happens in two main ways. To read more, go to the principle part.

Particle Size Reduction:

The combined impact and attrition grind the material down. Finer particles are carried towards the discharge outlet.

Advantages & Disadvantages of Ball Mill:

| Advantages | Disadvantages |

| Fine Grinding: It can reduce materials to extremely fine particle sizes, even down to the nanoscale | Noise: This generates significant noise during operation. |

| Versatility: They can grind a wide variety of materials, including hard, brittle, and even slightly sticky substances | Wear and Tear: Continuous impact and friction wear down the shell lining and grinding media, needing replacement. |

| Closed System: Ideal for grinding toxic materials or where a controlled atmosphere is needed (to prevent oxidation, etc.). | Energy Consumption: Ball mills can be energy-intensive, particularly for grinding hard materials. |

| Continuous Operation: Many ball mills allow continuous feeding and discharge, making them suitable for large-scale production. | Overgrinding: If not carefully controlled, there’s a risk of overgrinding materials beyond the desired size. |

| Simple Design: Their basic design makes them relatively simple to operate and maintain. | Potential Contamination: Material from the balls and the lining can contaminate the ground product. |

Conclusion:

Ball mills, despite their simple design, are powerful tools for transforming industries. Their ability to achieve fine particle sizes, handle diverse materials, and operate with precision makes them essential. While challenges like noise, wear, and energy consumption exist, their importance fuels advancements in technology.

If you need to learn more, please watch this video:

References to learn more:

- 911Metallurgist: Click here…

- SavRee: Click here..

- Digital Fire: Ball Milling: Click here…

I hope this provides a comprehensive overview of the Ball mill. And if you have any questions, feel free to ask!

3 thoughts on “Complete Guide of Ball Mill: All Things Here”